Gasification To Power Generation

WASTE TO ENERGY

Product Overview

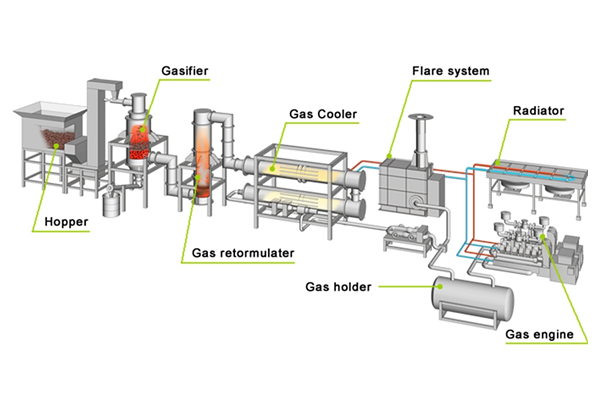

Gasification is a process that converts biomass, fossil fuel, and Solid waste-based carbonaceous materials into carbon monoxide, hydrogen and carbon dioxide. This is achieved by reacting the material at high temperatures (>700 °C), without combustion, with a controlled amount of oxygen and/or steam. The resulting gas mixture is called syngas (from synthesis gas) or producer gas and is itself a fuel. The power derived from gasification and combustion of the resultant gas is considered to be a source of renewable energy if the gasified compounds were obtained from biomass.

The advantage of gasification is that using the syngas (synthesis gas H2/CO) is potentially more efficient than direct combustion of the original fuel because it can be combusted at higher temperatures or even in fuel cells so that the thermodynamic upper limit to the efficiency defined by Carnot’s rule is higher (or in case of fuel cells not applicable). Syngas may be burned directly in gas engines, used to produce methanol and hydrogen, or converted via the Fischer–Tropsch process into synthetic fuel. For some materials, gasification can be an alternative to landfilling and incineration. Some gasification processes aim to refine corrosive ash elements such as chloride and potassium, allowing clean gas production from otherwise problematic fuels. Gasification of fossil fuels is currently widely used on industrial scales to generate electricity. Gasification can generate lower amounts of some pollutants as SOx and NOx, than combustion.

Gasification is a unique process that transforms a carbon-based material, such as MSW or biomass, into other forms of energy without actually burning it. Instead, gasification converts solid and liquid waste materials into gas through a chemical reaction.

Gasification converts MSW into usable synthesis gas or syngas. It is the production of this syngas which makes gasification so different from incineration. In the gasification process, the MSW is not a fuel but a feedstock for a high-temperature chemical conversion process. Instead of producing just heat and electricity, as is done in a waste-to-energy plant using incineration, the syngas produced by gasification can be turned into higher-value commercial products such as transportation fuels, chemicals, fertilizers, and even substitute natural gas. Incineration cannot achieve this.

The ash produced from gasification is different from what is produced by an incinerator. While incinerator ash is considered safe for use as alternative daily cover in landfills, there are concerns with its use in commercial products. In high-temperature gasification, the ash actually flows from the gasifier in a molten form, where it is quench-cooled, forming a glassy, non-leachable slag that can be used for making cement, roofing shingles, as an asphalt filler or for sandblasting. Some gasifiers are designed to recover melted metals in a separate stream, further taking advantage of the ability of gasification technology to enhance recycling.

Capacity

50 kw to 5 Mw

Leave A Comment